The Technical Breakdown of the Jeep 4.0 Engine: Design and Characteristics

The Jeep 4.0 engine, also known as the AMC 242 inline-six, is a legendary powerplant revered for its robust design, reliability, and off-road performance. While it may seem simple by today’s standards, the engineering behind this engine makes it a standout among internal combustion engines. In this article, we will delve deeper into the technical aspects of the Jeep 4.0 engine, exploring its design, materials, performance characteristics, and engineering decisions that made it one of the most beloved engines in Jeep history.

History and Evolution

Introduced in 1986 by American Motors Corporation (AMC), the 4.0 engine was a derivative of the 258 cubic inch inline-6. Designed to offer better fuel efficiency and performance, it became a staple for Jeep vehicles. After Chrysler acquired AMC in 1987, the engine continued to evolve with improvements in fuel injection, emissions control, and overall performance.

The 4.0 engine remained in production until 2006, powering various Jeep models such as the Cherokee XJ, Grand Cherokee ZJ, and Wrangler TJ. Its longevity is a testament to its well-engineered design and adaptability.

Technical Specifications

| Specification | Detail |

|---|---|

| Configuration | Inline 6-cylinder |

| Displacement | 242 cubic inches (4.0L) |

| Bore x Stroke | 3.88 x 3.41 inches |

| Compression Ratio | 8.8:1 to 9.2:1 |

| Power Output | 173-190 HP |

| Torque | 220-235 lb-ft |

| Fuel System | Multi-Port Fuel Injection (MPI) |

| Cooling System | Liquid-cooled |

| Valve Train | OHV (Overhead Valve) |

| Firing Order | 1-5-3-6-2-4 |

Key Features

- Cast Iron Block and Head

- The engine’s block and cylinder head are made from cast iron, which contributes to its durability and longevity.

- Multi-Port Fuel Injection (MPI)

- Introduced in 1991, the MPI system significantly improved fuel efficiency and performance.

- OHV Design

- The overhead valve design simplifies maintenance and contributes to the engine’s reliability.

- High Torque Output

- The 4.0 engine is known for its low-end torque, making it ideal for off-road applications.

Engine Block and Cylinder Head Design

Engine Block

The engine block of the Jeep 4.0 is made from cast iron, a material known for its durability and strength. The block features a deep-skirt design, which means the sides of the block extend below the crankshaft centerline. This design enhances rigidity and reduces vibration, making the engine more reliable under heavy loads and off-road conditions.

Key Specifications:

- Material: Cast iron

- Bore: 3.88 inches

- Stroke: 3.41 inches

- Displacement: 242 cubic inches (4.0 liters)

- Cylinder Configuration: Inline-six

The block has a six-cylinder inline configuration, which provides inherent balance and smooth operation. The long stroke of 3.41 inches contributes to the engine’s excellent low-end torque, a crucial feature for off-road driving.

Cylinder Head

The cylinder head is also made of cast iron and features two valves per cylinder (one intake and one exhaust). The simplicity of this design contributes to the engine’s durability and ease of maintenance. However, the head’s design has evolved over the years, with certain castings (such as the 0331 casting used from 2000-2001) being prone to cracking.

Key Features:

- Material: Cast iron

- Valves per Cylinder: 2 (1 intake, 1 exhaust)

- Combustion Chamber Design: Hemispherical

The hemispherical combustion chamber design promotes efficient combustion, improving both power output and fuel efficiency. The head gasket used in the 4.0 engine is a multi-layer steel (MLS) type, which provides excellent sealing and durability.

Crankshaft, Connecting Rods, and Pistons

Crankshaft

The crankshaft is forged steel, making it exceptionally strong and capable of withstanding high loads. The forged construction is a significant factor in the engine’s legendary durability.

Key Specifications:

- Material: Forged steel

- Main Bearings: 7

- Stroke: 3.41 inches

The crankshaft features seven main bearings, which provide excellent support and reduce flexing under load. This design choice contributes to the engine’s longevity, particularly in off-road conditions where the engine is subjected to significant stresses.

Connecting Rods

The connecting rods are also made of forged steel. They are designed to handle the high loads generated by the engine’s torque output. The rods use floating wrist pins to connect to the pistons, a design that reduces wear and extends the life of both components.

Key Features:

- Material: Forged steel

- Type: I-beam design

- Wrist Pins: Floating

Pistons

The pistons are made from cast aluminum alloy. They are designed to be lightweight yet strong enough to handle the high pressures inside the combustion chamber. The pistons feature a skirt design that reduces friction and wear against the cylinder walls.

Key Features:

- Material: Cast aluminum alloy

- Compression Ratio: 8.8:1

The relatively low compression ratio of 8.8:1 allows the engine to run on regular unleaded gasoline, making it more economical to operate.

Fuel Injection System

The Jeep 4.0 engine uses a multi-point fuel injection (MPFI) system. This system delivers fuel directly into each cylinder’s intake port, improving fuel atomization and combustion efficiency.

Key Features:

- Fuel Injection Type: Multi-point fuel injection (MPFI)

- Injector Placement: Intake manifold ports

- Fuel Pressure: 39-49 psi

The MPFI system replaced the carbureted systems of earlier Jeep engines, improving cold starts, fuel efficiency, and emissions. The fuel injectors are controlled by the engine control unit (ECU), which adjusts fuel delivery based on input from various sensors.

Ignition System

The ignition system of the Jeep 4.0 engine features a distributor-based system, which was later replaced by a coil-on-plug system in the final years of production.

Key Components:

- Distributor (early models): The distributor is driven by the camshaft and contains both the ignition rotor and a Hall effect sensor to determine ignition timing.

- Ignition Coil: Provides the high voltage needed to create a spark at the spark plugs.

- Spark Plugs: Copper core spark plugs are recommended for optimal performance.

In later models, Jeep introduced a coil-on-plug ignition system, which eliminated the distributor and improved reliability and performance.

Cooling and Lubrication Systems

Cooling System

The cooling system is a conventional liquid cooling system with a belt-driven water pump. The thermostat regulates coolant flow and helps maintain the engine’s optimal operating temperature.

Key Components:

- Water Pump: Belt-driven

- Radiator: Aluminum core with plastic end tanks

- Thermostat: 195°F (standard)

Lubrication System

The lubrication system is a wet sump system with a gear-driven oil pump. The oil pump is driven by the camshaft, ensuring consistent oil flow at all engine speeds.

Key Features:

- Oil Capacity: 6 quarts (with filter)

- Oil Type: 10W-30 (recommended)

- Oil Pump: Gear-driven

Performance Characteristics

Horsepower and Torque

The Jeep 4.0 engine is known for its impressive torque output at low RPMs, making it ideal for off-road driving and towing.

Jeep 4.0 Engine Specs Table

| Year Range | Horsepower | Torque | Compression Ratio | Fuel Injection | Notable Changes |

|---|---|---|---|---|---|

| 1987-1990 | 173 hp | 220 lb-ft | 8.8:1 | Carbureted | Initial launch with carburetor |

| 1991-1995 | 190 hp | 225 lb-ft | 8.8:1 | MPI | Introduction of Multi-Port Injection |

| 1996-2001 | 190 hp | 235 lb-ft | 8.8:1 | MPI | Refined for emissions control |

| 2002-2006 | 190 hp | 235 lb-ft | 9.2:1 | MPI | Final version with coil-on-plug ignition |

The engine’s torque curve is relatively flat, providing consistent power throughout the RPM range.

Jeep 4.0 Engine FAQ

1. Is the Jeep 4.0 a good engine?

Yes, the Jeep 4.0 engine is widely considered one of the best inline-six engines ever made. Known for its durability, reliability, and impressive low-end torque, it’s a favorite among Jeep enthusiasts for both daily driving and off-road adventures. Its simple design makes it easy to maintain and repair, contributing to its legendary status.

2. Is the 4.0 Jeep engine good?

Absolutely. The 4.0 Jeep engine delivers a great balance of power, torque, and longevity. It can handle tough off-road conditions while providing a smooth and reliable driving experience on the road. Many Jeep owners have reported these engines lasting well beyond 300,000 miles with regular maintenance.

3. How hard is it to rebuild a 4.0 Jeep engine?

Rebuilding a 4.0 Jeep engine is relatively straightforward for experienced mechanics due to its simple design and wide availability of parts. For someone with basic mechanical knowledge, a rebuild can be done with the right tools and guidance. However, if you’re inexperienced, it’s best to consult a professional.

4. How many miles will a 4.0 Jeep engine last?

The Jeep 4.0 engine is known for its longevity. With proper maintenance, these engines can easily last over 300,000 miles. Many Jeep enthusiasts report that their engines remain strong and reliable even after hitting high mileage marks. Regular oil changes and timely repairs are key to achieving this lifespan.

5. How much does it cost to rebuild a Jeep 4.0 engine?

The cost to rebuild a Jeep 4.0 engine typically ranges between $1,500 and $3,500, depending on the extent of the rebuild and the quality of parts used. Labor costs will vary depending on whether you do it yourself or hire a mechanic. Using high-quality parts can ensure a longer-lasting rebuild.

6. How much oil does a 4.0 Jeep engine hold?

The Jeep 4.0 engine holds approximately 6 quarts of oil, including the oil filter. Using the right oil type, typically 10W-30, is essential for maintaining the engine’s performance and longevity.

7. How much does a Jeep 4.0 engine cost?

A new or remanufactured Jeep 4.0 engine can cost between $2,500 and $4,000, depending on the supplier and the warranty offered. Used engines can be found for less, but it’s important to check their condition to avoid potential issues.

8. How long does a Jeep 4.0 engine last?

With proper maintenance, a Jeep 4.0 engine can last for 20 to 30 years or over 300,000 miles. Its cast iron construction and robust internals make it one of the most durable engines Jeep has ever produced.

9. What are the common issues with the Jeep 4.0 engine?

Some common issues with the Jeep 4.0 engine include:\n\n- Cylinder head cracks (0331 casting): Found in 2000-2001 models. Replacing the head with a revised casting solves this issue.\n- Rear main seal leaks: A common issue, but it can be fixed by replacing the seal.\n- Lifter and camshaft wear: Regular oil changes help reduce this wear over time.

10. What are the common power upgrades for the Jeep 4.0 engine?

Here are some popular performance upgrades for the Jeep 4.0 engine:\n\n- Turbocharger: Adds significant horsepower and torque. Requires careful tuning to maintain engine reliability.\n- Supercharger: Provides consistent power increases across the RPM range, enhancing both on-road and off-road performance.\n- Stroker Kit: Increases engine displacement to boost torque and horsepower. This is a popular mod for off-road enthusiasts looking for more power without sacrificing reliability.

Common Issues and Solutions

1. Cylinder Head Cracks (0331 Casting)

Some 2000-2001 models with the 0331 head casting are prone to cracking. This issue can be mitigated by replacing the head with a revised casting or an aftermarket option.

2. Rear Main Seal Leaks

A common issue with the 4.0 engine is a leaking rear main seal. Replacing the seal can be a DIY job for experienced mechanics.

3. Lifters and Camshaft Wear

Over time, the lifters and camshaft can wear out, leading to ticking noises and reduced performance. Regular oil changes can help prevent this issue.

Jeep 4.0 Inline-Six Engine: Building a High-Performance Stroker with Newcomer Racing

The Jeep 4.0 inline-six engine, celebrated for its durability and torque, has gained a loyal following among Jeep enthusiasts. However, this engine has untapped potential for increased performance. Newcomer Racing, a respected name in Jeep engine performance, demonstrates how to build a powerful stroker engine that maximizes horsepower and torque without breaking the bank.

Why Build a Stroker?

A stroker engine increases displacement by combining a longer stroke crankshaft with larger bore pistons. For Jeep 4.0 engines, the most common approach involves using a crankshaft and connecting rods from the older Jeep 4.2L engine (also known as the 258). This combination can yield up to 4.6 liters of displacement, significantly boosting power output.

Newcomer Racing’s approach to building a Jeep inline 6 engine stroker focuses on affordability and practicality for off-roaders, mud boggers, and racers. By carefully selecting components and performing critical machining, Newcomer Racing achieves impressive results.

Building the Jeep 4.0 Stroker Engine

Block and Crankshaft Selection

The foundation of any stroker build is the block and crankshaft combination. Newcomer Racing uses a 4.0L block, specifically a 449 casting from a 1999 Jeep Cherokee, known for its NVH (Noise, Vibration, Harshness) improvements and additional internal webbing for increased strength.

The crankshaft comes from an AMC 4.2L straight-six engine, specifically the lightweight version used in post-1981 models. This crankshaft features only four counterweights, reducing rotational mass and improving engine response compared to older, fully counterweighted versions.

Key Specs:

- Block: Jeep 4.0L, 449 casting

- Crankshaft: AMC 4.2L lightweight crank (post-1981)

- Bore: Increased to 3.905 inches

- Stroke: 3.895 inches

- Displacement: 280 cubic inches (4.59 liters)

Connecting Rods and Pistons

Newcomer Racing uses OEM connecting rods from the 4.2L engine, which are 5.875 inches long. The rods are upgraded with high-strength ARP bolts to ensure reliability under higher stress.

The pistons are Sealed Power hypereutectic castings with a small dish to maintain a pump-gas-friendly compression ratio. These pistons come with a 1.5mm ring package, offering better sealing and longevity.

Key Specs:

- Connecting Rods: 4.2L AMC, upgraded with ARP bolts

- Pistons: Sealed Power hypereutectic

- Compression Ratio: Pump-gas friendly

Camshaft and Valvetrain

The camshaft is critical in determining the engine’s power characteristics. Newcomer Racing uses a Bullet Racing camshaft with over 210 degrees of duration at 0.050-inch lift. The goal is to maximize torque and create a broad powerband suitable for off-road and street use.

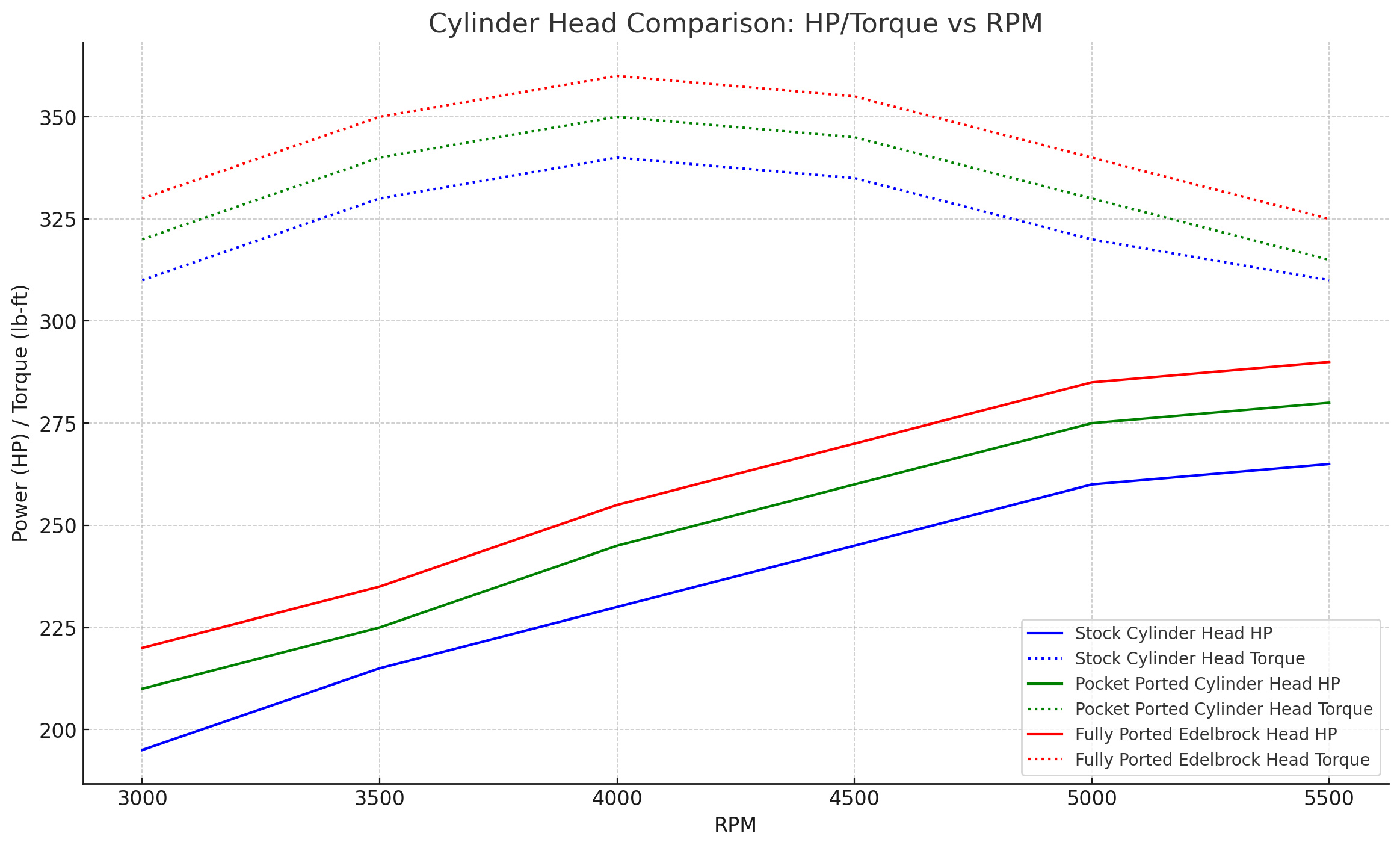

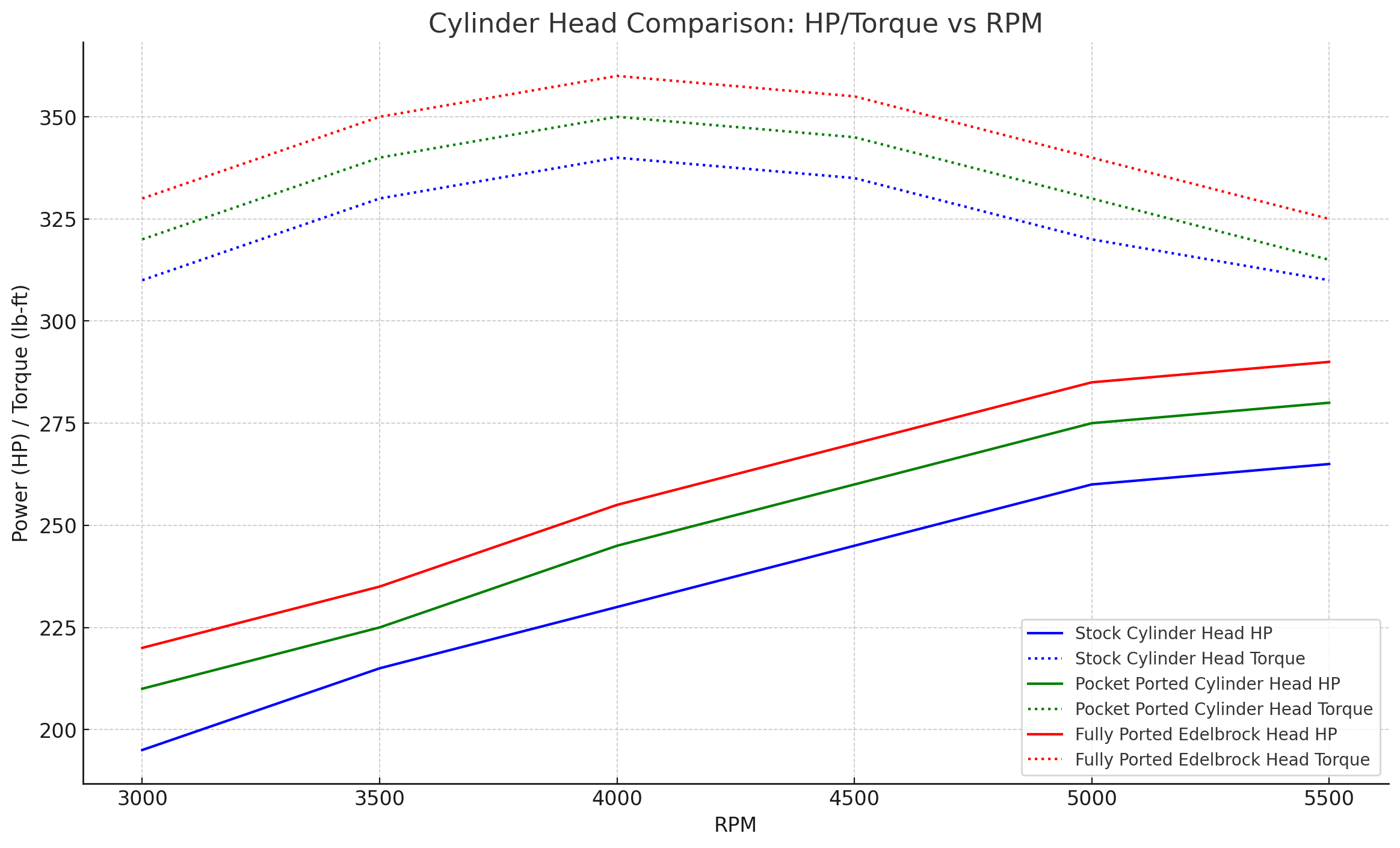

Stock replacement valve springs and retainers are used to keep costs down. However, Newcomer Racing offers upgraded heads with fully ported Edelbrock cylinder heads for those seeking maximum performance.

Key Specs:

- Camshaft: Bullet Racing hydraulic flat tappet

- Valve Springs: Stock replacement

- Cylinder Head: Optional Edelbrock ported head

Induction and Ignition

For induction, Newcomer Racing utilizes an aftermarket intake manifold modified to accept a Holley 4150-style carburetor or throttle body. A one-inch spacer is added to improve airflow. During dyno testing, a 950 CFM Holley double-pumper carburetor was used, though it is likely oversized for street use.

Newcomer Racing also employs a Holley Dominator ECU for those converting to modern EFI setups, along with Holley Smart Coils for a powerful and reliable ignition system.

Key Components:

- Intake Manifold: Ported aluminum aftermarket

- Carburetor: Holley 950 CFM double pumper

- ECU: Holley Dominator

- Coils: Holley Smart Coils

Dyno Results and Performance

The stroker engine performed impressively on the dyno. With a conservative setup, it delivered peak torque of 329.5 lb-ft at 4,500 RPM and 304.4 horsepower at 5,100 RPM. Compared to the stock Jeep 4.0 engine, which produces around 190 horsepower, this represents a significant improvement.

Dyno Summary:

- Peak Torque: 329.5 lb-ft at 4,500 RPM

- Peak Horsepower: 304.4 HP at 5,100 RPM

- Fuel: Pump gas

Newcomer Racing emphasizes that similar results can be achieved using the OEM EFI system with upgraded injectors and fuel pump. A retuned ECM is recommended to optimize performance.

Throttle Body and Intake Testing

Newcomer Racing conducted extensive testing of various throttle body and intake manifold combinations to find the best setup for the Jeep inline 6 engine. Four throttle bodies were tested, ranging from a stock 58mm unit to a 68mm aftermarket throttle body.

The tests showed that larger throttle bodies improve airflow, especially at higher RPMs. The 68mm throttle body from Painless Performance provided the best balance of low-end torque and high-end power.

Throttle Body Test Results:

- Stock 58mm: 293.7 HP / 331.3 lb-ft torque

- 68mm Aftermarket: 306 HP / 333 lb-ft torque

Newcomer Racing also tested both straight runner and curved runner intake manifolds. The curved runner intake provided better low-end torque, while the straight runner intake excelled at higher RPMs.

Intake Test Results:

- Curved Runner (Port-Matched): 319.4 HP / 342.1 lb-ft torque

- Straight Runner (Port-Matched): 320.4 HP / 346.3 lb-ft torque

The Jeep 4.0 inline-six engine can be transformed into a powerful stroker engine using a combination of affordable and readily available parts. Newcomer Racing’s approach to building a Jeep inline 6 engine focuses on maximizing performance without compromising reliability or breaking the budget.

Whether you’re building a Jeep for off-road adventures, daily driving, or racing, a stroker build offers significant power gains. By following Newcomer Racing’s formula and carefully selecting components, Jeep enthusiasts can unlock the full potential of their 4.0 inline-six engines.

Pushing the Limits: Inside a Jeep 4.0 Engine Turbo Build

Crazy things tend to happen whenever Newcomer Racing gets together with The Horsepower Monster on the dyno. This latest project takes the cake. What started as a straightforward test of a turbo setup with a ridiculous 11.8:1 compression ratio quickly spiraled into one of the most extreme builds the Jeep world has ever seen. Blowing things up, making massive horsepower, and potentially setting records—this session had it all.

The original goal was to test how the Jeep 4.0 straight-six would handle high boost paired with high compression. But the engine kept demanding more, and the team kept pushing further, ultimately surpassing 1,000 horsepower. That’s more than five times the stock output of a factory 4.0 engine, a power figure that few ever imagined possible for this platform.

Purpose Beyond the Dyno: Drag-and-Drive Rambler Race Car

One of the most exciting details about this build is that it’s destined for real-world use. The engine will likely find a home in The Horsepower Monster’s drag-and-drive Rambler race car, where it will put its street and strip credentials to the ultimate test.

Unlike a purpose-built dyno queen, this engine will need to endure long road miles between race tracks and handle repeated drag passes—all while retaining the reliability Jeep engines are known for.

Breaking Down the Madness: Why This Build Matters

The Jeep 4.0 engine is often thought of as a low-horsepower workhorse—reliable for crawling trails or daily driving but never considered a serious performance contender. However, Keith Newcomer continues to prove otherwise. His innovative approach to pushing the boundaries of what the inline-six platform can achieve has turned heads across the performance world.

From the fully counterweighted forged crankshaft to custom J.E. forged pistons, every detail of this build was designed to maximize both power and durability. But what really sets this project apart is the extreme combination of compression and boost, a recipe that typically leads to catastrophic failure—unless you get everything just right.

High Compression + Boost: The Recipe for Risk

Running 11.8:1 compression in a turbocharged application is practically unheard of. Most tuners would lower compression to keep detonation at bay. But Newcomer Racing took a different approach, using water-methanol injection to control intake temperatures and stave off knock.

Their gamble paid off—proving that with careful tuning and a deep understanding of how to manage airflow, timing, and fuel delivery, even extreme setups can hold together under pressure.

Key Performance Highlights

| Milestone | Result | Notable Features |

|---|---|---|

| Compression Ratio | 11.8:1 | High for a turbocharged engine |

| Boost Pressure | 27-30 psi | Managed through precise tuning |

| Turbo | Pulsar 77mm | Switched from 72mm for higher power |

| Peak Power | 1,000+ HP | Surpassed expectations |

Making History?

While it’s difficult to verify if this build set a definitive record, it’s safe to say that a 1,000-horsepower Jeep 4.0 turbo build is a rare and remarkable achievement. Few have pushed this engine platform to such extremes, and even fewer have done it with the intention of using the engine in a real-world racing application.

For Jeep enthusiasts, this build is a reminder that the AMC straight-six isn’t just a reliable plodder—it’s a platform with untapped performance potential waiting to be unlocked by those willing to push boundaries.

Whether you’re aiming for a modest 300-horsepower upgrade or dreaming of something more radical, the lessons from Newcomer Racing’s turbo build show that the Jeep 4.0 engine has what it takes to surprise everyone—even the experts.

Conclusion

The Jeep 4.0 engine’s design is a testament to robust engineering. Its cast iron construction, forged internals, and simple yet effective fuel and ignition systems make it a reliable workhorse. While not the most powerful engine by modern standards, its durability and low-end torque continue to make it a favorite among Jeep enthusiasts. With proper maintenance, the Jeep 4.0 engine can provide hundreds of thousands of miles of reliable service, both on and off the road.

For those looking to understand the technical aspects of this legendary engine, the details covered here showcase why the 4.0 engine has achieved its iconic status.